Oak Cliff Cargo Bicycles Is Doing Its Part To Make Dallasites Look At Cycling Culture Differently.

Slowly but surely, cycling culture is starting to catch on in Dallas.

Yeah, there's still a long way to go before cyclists and drivers will totally learn to safely and harmoniously share the road, but there are many indicators that we're, at least, headed in the right direction. For instance, there's the fact that we're only about two years away from a network of bike trails connecting Dallas and Fort Worth being completed.

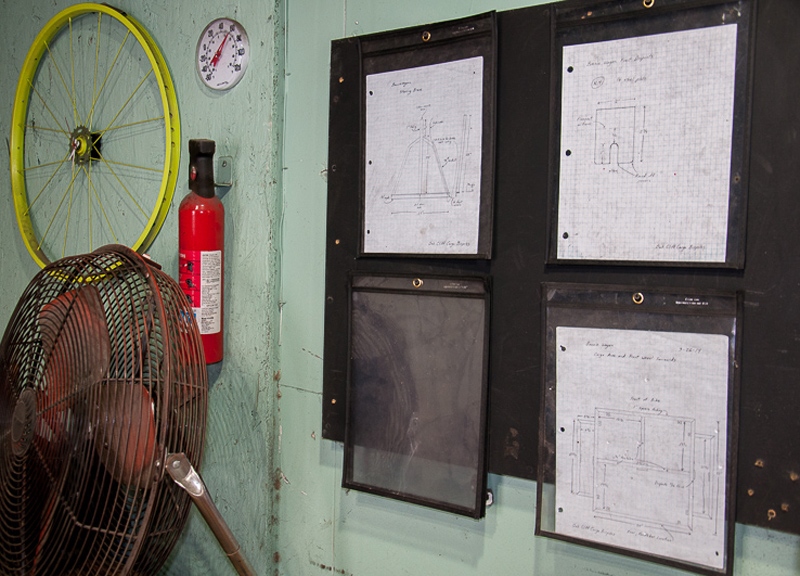

Meanwhile, down in Oak Cliff, a neighborhood that always seems to be ahead of the rest of the city when it comes to embracing different aspects of cycling culture, some interesting things are happening on the bike manufacturing front as well. Over the course of the past two years, Jonathan Braddick and Brennen Bechtol have been converting recycled bike frames into truly beautiful, custom cargo bikes that can be used by vendors to haul around product, by parents to haul around kids or by just about anyone to haul just about anything.

Thus far, their company, Oak Cliff Cargo Bicycles, has been somewhat limited by the fact that most of the materials they use to build their frames comes from recycled or scrapped materials. In the future, the pair would like to ramp up production by taking part in training and buying machinery that would allow them to manufacture their own frames from scratch.

Still, their model is an intriguing one as is. So we caught up with the pair to find out more about their interesting little company.

You started Oak Cliff Cargo Bicycles in 2012. How many bikes have you made since you started, and how long does it take to make each bike? With each of those 26 bikes, is it a client that asks for them each time or are you selling them to bike shops? Currently, you use recycled bike frames. Where do you get these? So when you learn how to make the frames yourselves, will there be just a single frame you'll use for all the bikes or will you learn to create different kinds? How do you plan to get the material for this new frame? So you're not currently doing this process now because you need to learn how to make it first? So far, what has been your favorite project? What did the bike carry for them? How do you come up with the original designs of these bikes? What do you want them to be used for? If someone were to bring you a frame they wanted to be built in a bike, could you do that? As far as your first customers: Who is using their bikes in their daily life? Are you trying to include this into your overall bike advocacy mission? Do you want people to start using your bikes instead of their cars and just incorporating them more into Dallas life? How do envision people using these bikes? Is it mainly for their work or for their daily life? So the kids are able to fit in the box? So these are reasonably large bikes if you're going to be able to put children in there. Do you think the types of clients that you're selling to now will change? What do you see happening on that end? Do you see it expanding?

Braddick: Since we first started, we have completed 22 bikes, and we have four outstanding bikes at the moment. So, about 26 total have been purchased.

Bechtol: “It all depends on the model. Like, the current one we have going doesn't take very long because there's not a lot of welding or fitting pieces together. But, on average, it takes one to two months to fully complete one build. That includes finding the donor frame, materials, having all that come in, starting the cutting and then the powder coat. So there's a lot of steps that happen in between finding the frame and delivering it to the customer, and it all depends on which model we build.

Braddick: We are our own shop. We sell directly to our clients. However, we just established our first dealer, located in Austin, called Tsunami Cycles on South Congress. They'll be selling our bicycles for us using a wholesale model, but we still sell directly to people outside of that distribution area. We're selling direct to our clients, which come from all over the country — San Fransico, Upstate New York, Illinois, Colorado, Salt Lake City, Minnesota, Chattanooga, Atlanta, the list goes on. Most of our clients have been outside of Texas. We have sold a few locally but. in other markets. these bikes are more well-known and more popular so far.

Bechtol: We get them from a source in West Dallas that has bikes donated to them. They are a non-profit so they get a good amount of bikes given to them. So we can choose from them and pick out what we need. The issues that we run across with recycled bikes is that we can't always find the right size or the right type of frame that we need.

Bechtol: The back end will be pretty standard on most bikes. We will be able to customize the sides better to fit the customer's needs according to their body dimensions and in order to make the bike work the best way it can for them. We'll also be able to do some things on the back of the bike that will help out with the basic mechanics of the bike to make sure everything works properly.

Braddick: With recycled frames, we're kind of fixed to one box. But when we're able to use a scratch frame, we can do a lot more. We can plan accordingly for advanced mechanical componentry, have a little bit better quality. We have a great standard quality we put into our standard bikes, but, with all bicycles, they come in different sizes and prices. We want to be competitive within the cargo bike resurgence happening in the United States now, and we want to be competitive with the other companies. So, to do that, we feel we need to build a higher-end bike to complement our recycled bikes.

Braddick: There are companies we can source all of our tubing and various parts that we need to weld to make the new cargo bike frame.

Braddick: Correct. We established this company from kind of a DIY perspective. Brennen and I come from being bicycle enthusiasts and advocates here in Oak Cliff, however we hadn't yet acquired that advanced bike-building knowledge prior to starting. We thought we could start our company with the DIY approach and try to make it work and be successful — and so far we've done that. But we want to improve upon our products, knowledge and education in the bike building world.

Bechtol: One of the ones we did was for a company, a couple gals out of Grapevine, and they wanted a bike to sell their product on. The name of that company is called ReGEARED.

Braddick: …who happen to be one of the vendors we outsource our wood from.

Bechtol: Right. They make all the boxes and woodwork we install on our bikes. So that was a pretty fun project.

Braddick: It looked like the spaceship from Star Trek. What's the name?

Bechtol: The Enterprise.

Braddick: It looked a little bit like that. It's on our website, and it's a really unique bike. It was built from an old Schwinn cruiser frame, so it has those old nostalgic stylings to it.

Bechtol: That's the great thing. They use it a lot. That's what we want of our bikes — to get used not to just kind of sit in someone's garage. They use it for events where they go set up and sell at events and put their product on it. It's traveled all over the country. They also use it just for little things like taking packages to the post office to just load up boxes on it and ride on over.

Braddick: So, like, from their shop, they'll do short trips or put it in the back of their truck to take it to an event. They can then take it to an event and they've got a lot of product, so they'll put that in their bike and then ride to where their spot is. So it's multipurpose.

Bechtol: With a lot of things, it's already been done, so all you have to do is look at what's been done in the past. So we looked at bikes that are used in Copenhagen — the Dutch-style bikes — and we also looked at what's currently being produced and tried to figure out what are people looking for in a cargo bike. So those are a couple things we kind of referenced.

Braddick: Right. And, also, our styling happens to be unique because we used recycled bike frames and we get to delve into about 50 years of bicycle frame building and what their styles are and what they look like. So when you buy a bike from us, you're basically getting a one-of-a-kind, custom bicycle every time when it comes from our recycled frames. Because I take an old Schwinn frame or an old Raleigh frame and they have different styling, they built the frames differently, so we have almost a nostalgic, old-school, retro styling that comes with our bikes. I think that's what has appeal to our people about us as well.

Braddick: They can – and then they get $50 off their order as well when they do that. So we've had a couple people do that.

Braddick: I think the answer to that question is yes and no. And I'll explain why it was first yes. We did the cargo bike workshop. Brennen came to that workshop. My thought was, I wanted to introduce Dallas to cargo bikes. Also because we do speak about doing more without our car, then, yes, it was an advocacy prospective. But when Brennen finished the course and I noticed he had already built two bikes and we started talking, we thought, “Let's give this a go.” And we thought it would be more a mission of ours to see if we could establish this company here in Dallas. So it has both its roots in advocacy as well as a mission to have our own company.

Bechtol: Well, we've gotten requests from both families and companies and individuals. It seems as though it's been kind of a 50/50 split. Although, lately, we've gotten a lot of interests from just individual families. One we just sent to Atlanta — they have two kids, smaller kids, and it was one of our Bonnie models. It has a box and it's a two-wheel model. So they use it to just ride their kids around.

Bechtol: Yeah! There's a couple little benches in the box and they can sit down in there and there's some straps where they can strap them in.

Bechtol: Well, it depends on the model, but the wheelbase is just under eight feet, so it's obviously longer than a typical bike. But you need that in order to have that cargo space.

Braddick: They're a little larger than conventional bicycles of course because you're hauling either people or items. But, to go along with your question, we get a lot of inquires also from companies looking to do mobile businesses because we sell a model, the Ivan, where we've built espresso cargo bicycles for Toms and another company in Utah called Blue Copper. They actually ride the bike from one place to another to sell their product. So I've had juice companies contact me — you name it, gin, beer, crepes — so a lot of it has been a lot of research for them, as for what new business they want to establish. We can adapt our Ivan model to any kind of food or beverage distribution or, like, the very first one that Brennen mentioned, simply for just selling their product, y'know? It's a great market for companies.”

Braddick: Yeah, as far as our customers changing, I think that people will evolve — people that don't know about cargo bicycles. Obviously, you're learning about them today. What I mean by evolve is simply just that we're such a small company, and it is such a small, little, niche market within the bicycle industry that it's still very, very new. Cargo bicycles have been around for years and mainly in the United States they've been used as a means for companies to establish their businesses. Now, because cities all over the country, including Dallas, are looking at ways to be more efficient with their dollars, the cargo bicycle is a very efficient tool to do that. So I think that evolution will continue to take shape in large cities. Atlanta and Dallas and all the southern states are becoming more aware of how they need to change and adapt to the new realities of either gas prices going up or all the different issues that we face. So I think they'll continue to learn more about cargo bicycles and other companies' cargo bicycles. And hopefully that will continue to help up sell some bicycles.